Your Partner for Developing Cargo Containment Solutions

Tulmar Safety Systems Inc. is a designer, manufacturer of engineered protective equipment and survivability solutions for the aerospace and defence markets worldwide.

The company’s products range from highly specialized protection equipment for military vehicles, inflatable life support and flotation products for military and aerospace applications as well as specialized cabin crew training equipment sold to airlines around the world. Products are supported through a fully certified repair and overhaul division.

Working for more than 25 years with large OEMs as an integrated solutions provider, we assist our customers in various ways including design, development, certification and manufacturing.

Specific to cargo containment systems, below are 3 examples of projects we undertook with our customers to adapt solutions to their needs.

Case 1: Much-needed stowage solutions for the Tilt-rotor V22 Osprey

The Problem

On the Bell/Boeing Osprey crew and passengers lacked the ability to stow small items typically carried in the cargo compartment. Operators needed a solution for securing common items the aircrew brought aboard.

The Solution

Tulmar designed for the US Marines a specialized twin net system installed forward and aft of the MAT(s) to enhance storage and accessibility. The net solution turns a pair of wall tie‐down points into a centralized area for securing aircrew items. Key advantages include:

- The net design gets small items off the floor to allow maximum space for cargo/team members.

- Items are consolidated in one area improving overall cabin security

The design was certified by NAVAIR (Naval Air Systems Command) and has been in use since 2011.

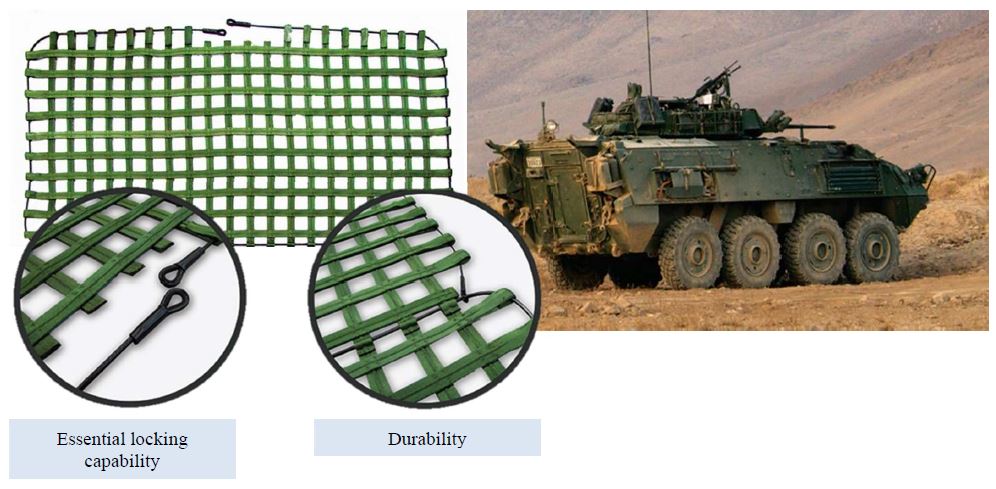

Case 2: A new lockable net system for General Dynamics Land Systems (GDLS)

The Problem

During the Afghanistan conflict, DND stowed equipment for the Light Armored Vehicles (LAV) crew on the side of the vehicle in stowage bins. These stowage bins could easily be accessed by simply cutting the nets and removing the contents. GDLS had a requirement to ensure that these nets could not be cut or destroyed.

The Solution

Working collaboratively with GDLS, Tulmar designed a lockable, theft deterrent heavy-duty net system to protect the contents in the stowage bin. This solution is now being successfully deployed on the LAV III upgrade program in use around the world.

Case 3: Developing a high-capacity cargo net for a world-leading helicopter equipment manufacturer

The Opportunity

For commercial helicopter operators cargo capacity is a key mission requirement. Our customer, a market leader in the design and manufacture of innovative product solutions for the global helicopter market wanted a net that provided an advantage over the existing OEM product in terms of:

- restraining more cargo with a single net;

- enabled optimal use of the available cargo space; and

- enabled quick loading and unloading, effectively reducing ground handling workload.

The Solution

The net collaboratively designed with our customer is a high capacity cargo net solution offering the following advantages:

- Increases the cargo capacity of the AW139 by up to 30%;

- Is approved for loads up to 820 lbs. (373 kg) compared to 660 lbs. (300 kg) with the OEM net;

- It increased the maximum cargo height by 7 inches or 18 cm, an additional 30%;

- Loading activities are easier and faster to complete owing to the net suspension design and strap buckle placement;

- It can be loaded by 1 person from 1 cargo door;

- It also includes a mesh net to unitize loads consisting of multiple smaller items, preventing small articles from escaping tie down straps and becoming loose in the cargo compartment.

Supporting Capabilities

- Development engineering

- In house load, strength testing

- External qualification testing

- TDP creation

- Prototyping

- Manufacturing

- Assemblies & kitting